Thin Metal Sheets

15047 Sierra Bonita Lane

Chino, CA 91710

T: (909) 393 2273

F: (909) 393 2811

Email: support@thinmetalsheets.com

15047 Sierra Bonita Lane

Chino, CA 91710

T: (909) 393 2273

F: (909) 393 2811

Email: support@thinmetalsheets.com

Width |

N/A 24 in |

Length |

N/A 24 in |

Alloy |

N/A T301 Stainless Steel Alloy |

Thickness |

N/A 0.0060 in |

Thickness Tolerance |

N/A 5 % |

American Society for Testing and Materials (ASTM) Steel Standard |

N/A ASTM-A-666 |

Aerospace Material Specification (AMS) |

N/A AMS-5518 |

Alloy Steel Type |

N/A Stainless Steel |

Material Form |

N/A Sheet |

Temper |

N/A Half Hard Temper |

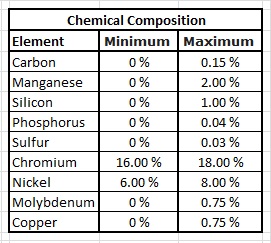

Maximum Carbon Composition |

N/A 0.15 % |

Maximum Manganese Composition |

N/A 2.00 % |

Maximum Silicon Composition |

N/A 1.00 % |

Maximum Phosphorus Composition |

N/A 0.04 % |

Maximum Sulfur Composition |

N/A 0.03 % |

Maximum Chromium Composition |

N/A 18.00 % |

Maximum Nickel Composition |

N/A 8.00 % |

Maximum Molybdenum Composition |

N/A 0.75 % |

Maximum Copper Composition |

N/A 0.75 % |

Chemical Composition Table |

N/A

|